When building a custom AR-15 upper receiver, installing your barrel is actually one of the easier things to complete. Make sure and read the article that covers what tools you will need to build your AR-15 upper receiver and then grab the following items: your barrel, your barrel nut, torque wrench, barrel nut wrench and AeroShell 33ms grease.

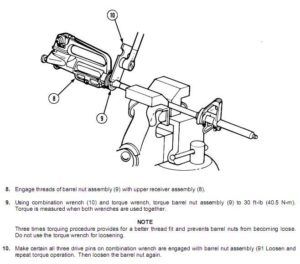

If you decide to install your own barrel into your AR-15 upper receiver, it is important to make sure your upper receiver is well supported to be able to withstand the stress it will have to endure when you’re torquing down the barrel nut. In the image to the left from the technical manual I use, you can see that you may also opt to place your barrel directly in the vise. However, if you are not careful, you could damage your barrel significantly. I have used an upper receiver vise block in the past without issues, but I have since obtained a Geissele Reaction Rod which I am more confident using and will continue to use in the future.

With that said, let’s get your upper receiver or barrel secured in a fashion you are comfortable with, and lets get that barrel installed, shall we?

Liberally apply AeroShell 33MS grease to both the threads of the barrel nut and the upper receiver, slide the barrel nut over the barrel, and hand tighten the nut. Using the torque wrench and barrel nut wrench, torque the barrel nut to 30 foot pounds.

More than likely, exactly 30 foot pounds will not allow for proper gas tube alignment with the barrel nut, so I typically “season the threads” by tightening, loosening and re-tightening the barrel nut a few times.

Continue to check for proper gas tube alignment that is specific to your barrel nut. This generally means that when the barrel nut is timed correctly, the gas tube will be able to move straight and without hangups through either a notch or hole in the barrel nut and into the upper receiver.

Once you torque the barrel nut to the initial 30 foot pounds, set the torque wrench for 80 foot pounds and continue to tighten the barrel nut until the correct timing is achieved. More than likely you will not reach the mil-spec cut off of 80 foot pounds before the barrel nut is properly timed. If you do end up reaching the 80 foot pound limit and your gas tube alignment is still no good, you may have to use a shim.

Be sure to check back next week for when I explain how to install the gas tube into the gas block and install it on the barrel.