If you’re following our AR-15 upper build how-to, we’re ready for the last step: installing a muzzle device (flash hider, muzzle brake or compensator). Fortunately, it is a simple process and I am going to share with you exactly how I do it, step by step. There is an incredible amount of muzzle devices currently available on the market, but for simplicity’s sake, I will be covering how to install a typical A2 “birdcage” style flash hider. For the most part, almost all muzzle devices can be installed using the same basic techniques I will discuss in this guide.

Items Needed

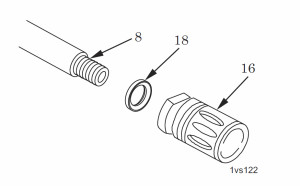

- A2 flash hider

- Crush washer

- ¾” wrench or armorer’s tool

- Bench vise

- Upper receiver vise block

- AeroShell 33MS grease

Installing the Muzzle Device

In my opinion, the most important part of this process is making sure your barrel and upper receiver are held securely in a vise. This is important because you will be placing a decent amount of torque on the end of the barrel and you do not want it to move. You may opt to clamp your barrel directly in the vise or use an AR-15 upper receiver vise block. I recently obtained a Geissele Reaction Rod and recommend it because it only applies torque to the barrel extension rather than the aluminum upper receiver.

Once you have your barrel and AR-15 upper receiver secured, install the crush washer with the small end against the barrel and the large end flaring outward. Now, liberally apply some AeroShell 33MS to the threads of the barrel and hand tighten the flash hider.

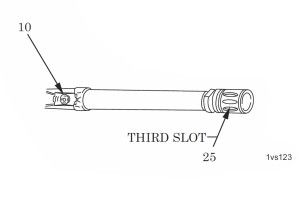

Using a ¾” wrench, tighten the flash hider until the third slot is facing straight up and is in direct line with the font sight post or gas tube. This procedure is called “timing.” By making sure you line everything up correctly, you are “timing” your flash hider.

When using a crush washer, do not tighten/rotate the muzzle device more than 450 degrees when installing it. If you cannot properly time your flash hider within that value then remove your flash hider and crush washer and start over with a new crush washer.

If you are having trouble rotating your muzzle device to get it to time correctly, try this: loosen it, re-tighten it and then repeat until you get it lined up the way it should be. Also, a bit of advice from experience: do not over tighten your muzzle device. Tighten it just until proper timing is achieved and then leave it.

Your AR-15 upper receiver is now complete and is ready for you to install your rail, attach your optic and accessories—congrats!